When looking for high-quality ASME/ANSI B16.47 Series B Weld Neck Flanges to join pressurized piping systems safely and reliably, experienced engineers know to turn to industry leader Carbon Steel Flanges. As a globally recognized flange manufacturer and supplier, Carbon Steel Flanges maintains an immense inventory of B16.47 Series B Weld Neck solutions tailored for the most demanding industrial applications. In this 3,000+ word guide, we'll explore what sets Carbon Steel Flanges apart as the premier source for these specialty flanges.

Understanding ASME B16.47 Series B Weld Neck Flanges

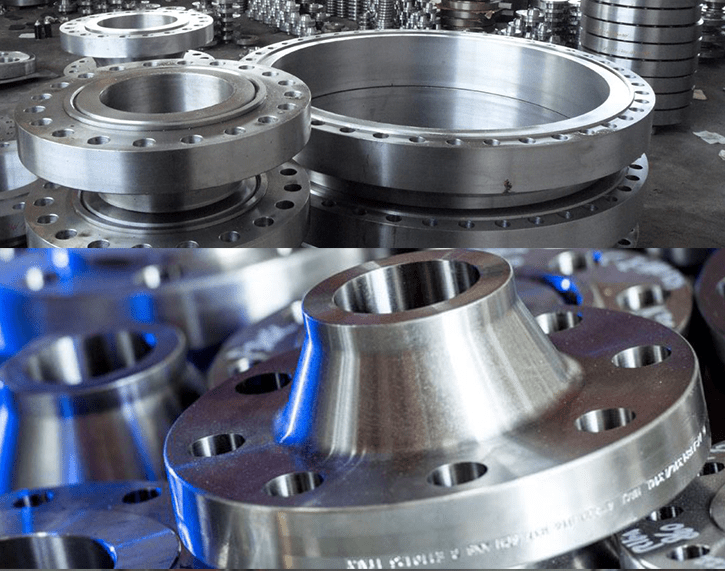

First, let's define what exactly an ASME/ANSI B16.47 Series B Weld Neck Flange is. These flanges adhere to standards set forth in ASME/ANSI B16.47 for dimensions, tolerances, materials, testing procedures and more. They feature a long tapered "neck" protruding from the flange face, designed to provide a flush butt-welded connection directly to pipes.

This welding neck greatly enhances joint strength compared to other flange styles like slip-ons. It also allows precisely controlled gaps between joined pipes and flanges for non-destructive testing. ASME B16.47 Series B Weld Necks are commonly specified for applications involving high pressures, temperatures, loads or critical media transfer under regulated conditions.

Global Inventory at Your Fingertips

As the go-to supplier of ASME B16.47 Series B Weld Neck Flanges worldwide, Carbon Steel Flanges helps projects stay on schedule by stocking practically any size or specification your plant requires. Their immense in-stock selection covers dimensions from 1/2" through 60" across all pressure classes - from 150# up to 2500# and beyond.

Whether you need a few units or bulk packaged orders of thousands, Carbon Steel Flanges' expansive warehouses paired with rapid fulfillment ensure you receive the right flanges when needed. For specialized projects, their engineering experts also happily provide CAD drawings and material samples to guarantee a perfect custom fit.

Compliance You Can Trust

In addition to superior selection, buyers turn to Carbon Steel Flanges for the assurance that every B16.47 Series B Weld Neck Flange adheres strictly to regulating standards. They manufacture all products in accordance with ASME B16.47 guidelines as well as international regulations like EN, JIS and GB.

Buyers can specify any alternate facings, additional testing, special coatings or other requirements with full confidence Carbon Steel Flanges will deliver compliant, certified solutions on-spec and on-time. These stringent quality controls provide peace of mind for plants operating under regulated industries.

Range of Materials for Any Need

While many suppliers stock standard carbon or stainless varieties, Carbon Steel Flanges excels through choice - offering B16.47 Series B Weld Neck Flanges fabricated from an extensive range of corrosion-resistant materials. This includes carbon steel, stainless steels like 304/316L as well as high-grade alloys suited to chemicals, oil/gas, power and other harsh duty applications.

Customers receive optimum material selection advice from flange application specialists. With coatings, special finishes and even dual certified material options, Carbon Steel Flanges ensures the longest service life from these critical joints under diverse process conditions.

24/7 Expertise Support

Beyond deep product inventory and stringent quality, another reason engineers trust Carbon Steel Flanges is their dedicated team always standing by to help. Buyers benefit from sales, customer service and technical staff who provide multi-lingual guidance anytime via phone, email or live chat.

Whether outfitting a new plant, upgrading existing systems or solving dilemmas in the field, friendly experts assist with part numbers, install tips, drawings and more. Carbon Steel Flanges even welcomes OEM partnerships for engineered solutions to specialized piping challenges. It's this level of responsive, personalized support keeping customers returning project after project.